Chicago Winter Dining Challenge

As a Chicago-based firm, we understand that the food industry largely impacts the local economy and city’s vibrancy. This solution will allow Chicago businesses to offer safe and comfortable outdoor dining during the winter months.

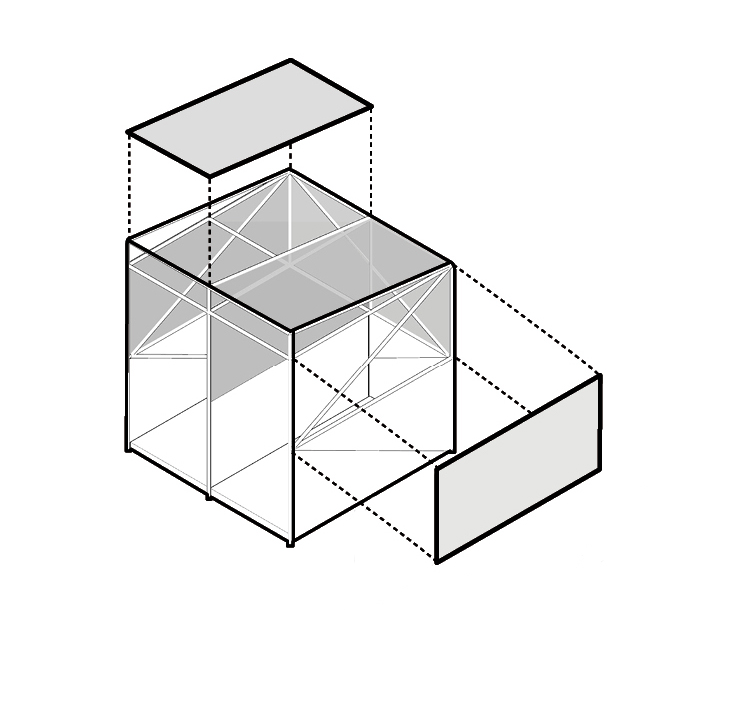

This simple and adaptable kit-of-parts provides users a base module that can be used as an exterior structure. The design allows for a variety of options which are adaptable to the evolving and unique needs of various restaurants and eateries.

The design approach for HYGGE HUT is a fully modular “kit-of-parts” that is built around the idea of fast and easy prototyping and construction. Through the use of standard materials and standard sizing, the construction approach is simple and feasible. Small teams can be deployed to deliver and construct the module(s) quickly due to the integration of known assembly methods and standardized components.

The structure and materials were selected to protect guests against winter weather scenarios while also keeping air flow a priority. Heated floor panels also keep diners warm and comfortable.

One module fits one table to allow for self-contained units and limit cross contamination. These modules can be duplicated and expanded relating to each individual business. Modules can be customized, allowing each restaurant to express an independent identity. All customization will respond to the cost constraints of the eatery.

Each module can be assembled using base construction materials, providing a realistic solution and allowing for the greatest cost effectiveness possible. If desired, the framing system and cladding panels can be upgraded and customized to provide a higher quality of finishes and a unique identity. Existing scaffolding cladding systems, such as the Layher system, can be integrated to provide an even further level of customization.

Each module provides an integrated radiant floor heating system that efficiently controls the climate. While the heating system is activated, all side panels are in an enclosure mode to capture the heat and allow for protection from the elements. As seasons change, modules can adapt to warmer weather by providing operable panels that can open to allow for greater ventilation while still providing shelter from the rain and shade from the sun.

Finally, each module can be fully closed to provide security during off hours and overnight.

By combining our firm’s expertise in architecture with consultation from multiple construction industry partners, our team was able to produce an efficient outdoor dining product that adapts to the needs of restaurants.

Using cost-effective but reliable materials in accessible finishes and sizes, a program to supply restaurants with this kit-of-parts is feasible. Understanding that the restaurant staff would be assembling these modules, the process to do so is quick and attainable due to the module’s overall design and material selection. We have partnered with Designed Equipment Co. to consult on wall paneling, ensuring the structure is safe and stable.

All modules are based on standard detailing and assembly; customization can be added at the discretion and budget of individual businesses. By creating one base module, which can adapt in response to the needs and scale of the restaurant’s operations, resources are protected.

Our design was inspired by the ethos that has been built around a love of sharing food. We believe the product we’ve devised is a viable option for all business types and will create possibilities for an industry that employs thousands of hard-working individuals.

The module design can easily fit in parking spots and on the edges of unused sidewalks. Even businesses with very limited outdoor space can be accommodated. As such, any neighborhood across Chicagoland could utilize this module design.

User safety dictated the overall design and function of these modules; the team understands the health and safety of guests is a main priority of this project. The roof structure is designed to allow for constant, fresh air flow while a heated floor system ensures guests remain comfortable. Polycarbonate panel siding can be easily cleaned, and additional antimicrobial surfaces can be implemented.

Finally, all modules are self-contained, ensuring there is no cross contamination between different parties attending the same restaurant.